Research Projects

Design and Development of the First Dynamic Bileaflet Mitral Bioprosthesis

Heart valves play an important role in directing blood flow and preventing back flow in the heart. Design and development of bioprosthetic heart valves has been a major focus of research in the field of cardiovascular engineering as they are a better replacement for natural diseased valves than mechanical heart valves. However, one of the major problems facing bioprosthetic heart valves involves excessive stress around the tip of the leaflet which can lead to calcification. Reducing this stress can potentially increase the valve.s longevity and will result in a lower risk of fatigue and leaflet tearing, and ultimately minimize the chance of valve degeneration and failure.

Heart valves play an important role in directing blood flow and preventing back flow in the heart. Design and development of bioprosthetic heart valves has been a major focus of research in the field of cardiovascular engineering as they are a better replacement for natural diseased valves than mechanical heart valves. However, one of the major problems facing bioprosthetic heart valves involves excessive stress around the tip of the leaflet which can lead to calcification. Reducing this stress can potentially increase the valve.s longevity and will result in a lower risk of fatigue and leaflet tearing, and ultimately minimize the chance of valve degeneration and failure.

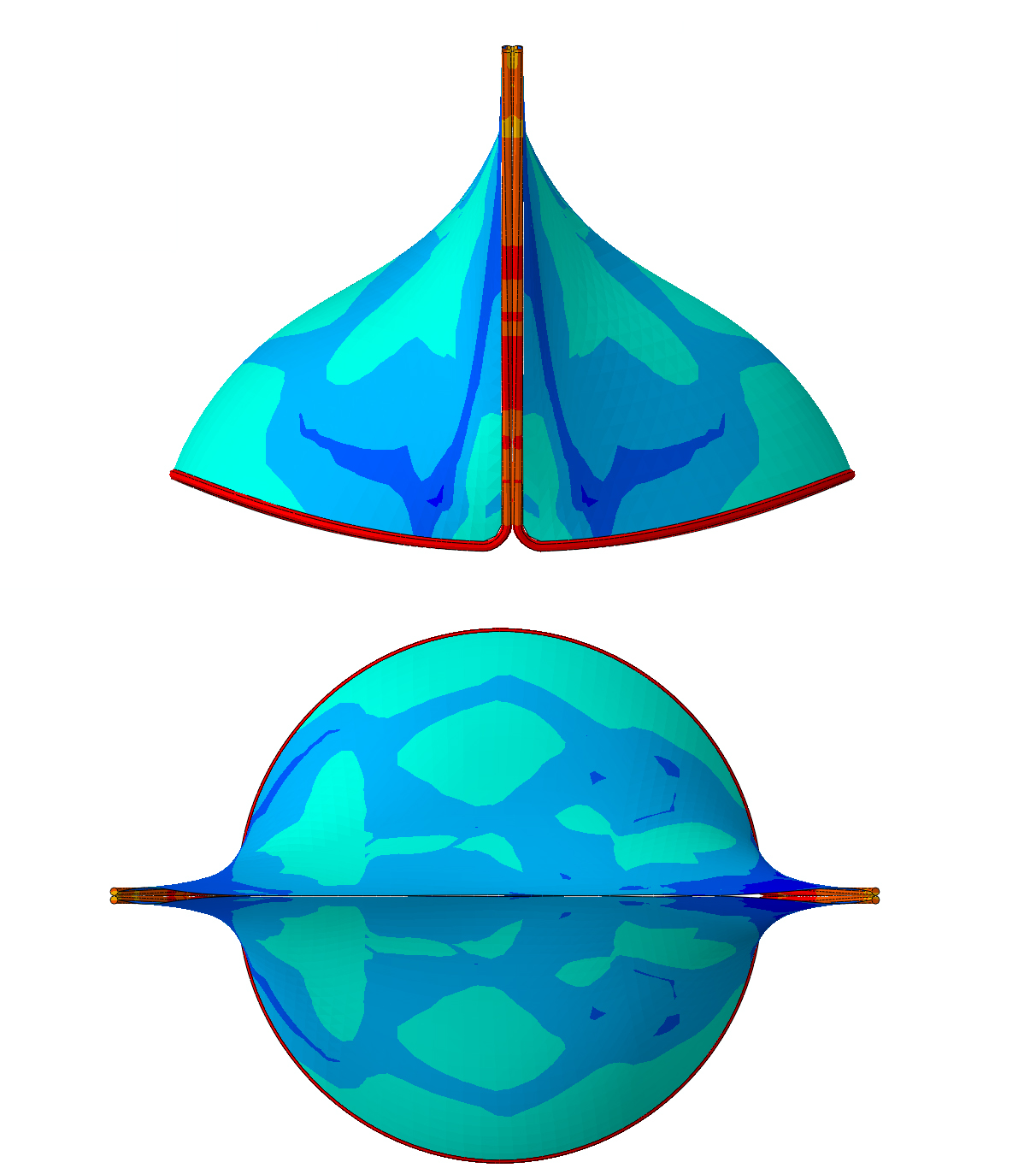

This project is focused on the assessment of mechanical behavior and optimization of a bi-leaflet bioprosthetic mitral valve by using Finite Element Analysis. The latest constitutive law for the tissue is employed, which takes into account the tissue's dependency on fiber direction. The framework of this study can be easily used to design, analyze, and optimize all types of bioprosthetic heart valves.

To model the stress distribution over the valve.s leaflets using the finite element method, the solid geometry of the Nitinol framework and the leaflets were developed independently and then imported into a computational analysis software environment. We used CATIA V5R19 (Dassault Systès, Lowell, MA) as our mechanical design software and ABAQUS 6.9-EF1 (SIMULIA, Warwick, RI) for computational analysis. Material behavior of the Nitinol framework was modeled as a superelastic material. The constitutive models for the mitral leaflets were adopted from May-Newman and Yin. A user-defined code has been written to apply this strain energy function using UMAT user subroutine in ABAQUS. ABAQUS/STANDARD was used for this simulation. Results show the saddle annulus motion of the valve mitigates the stress over the leaflets, and can potentially reduce the chance of leaflet mechanical failure. This is due to the dynamic saddle annulus which adapts a configuration with the lowest energy.

View all research projects